JEI Turbo Steel HSS Mag Drill Cutter 19mm shank

From £16.81

Description

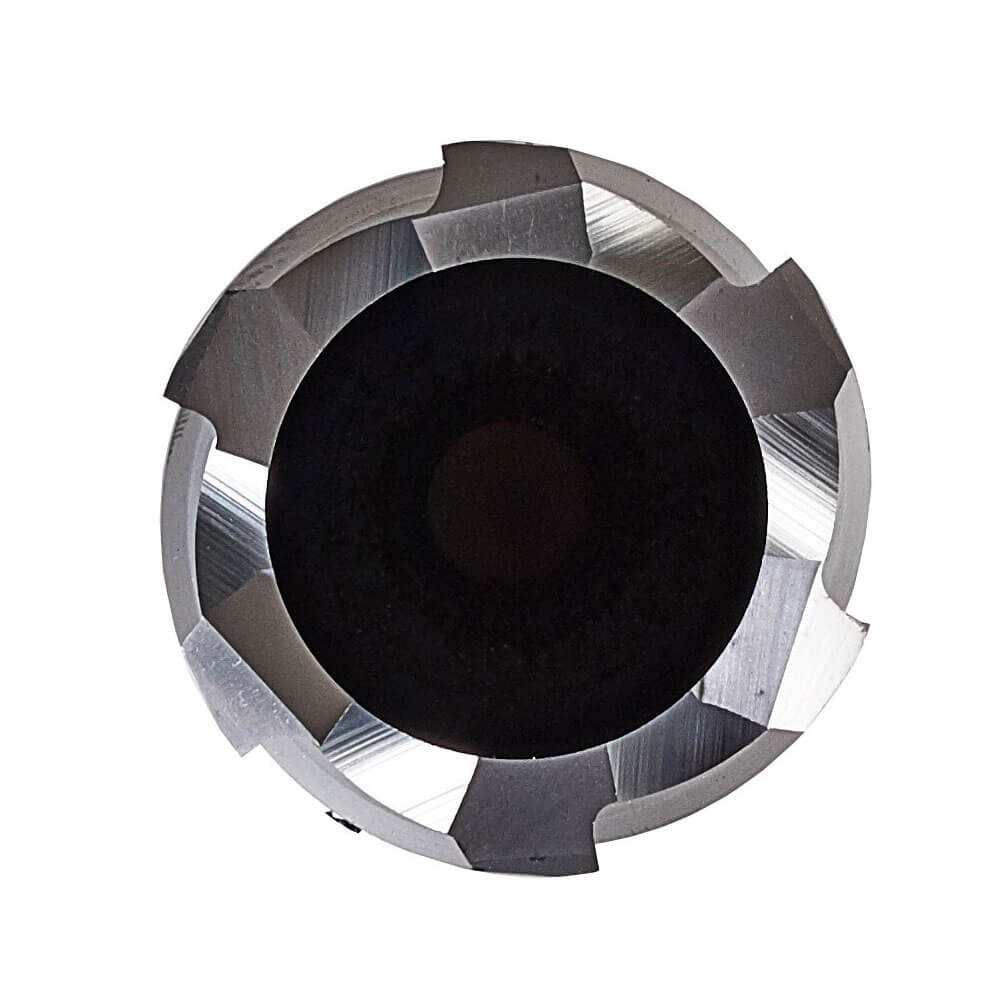

Step up your hole drilling productivity with JEI Turbo Steel HSS Mag Drill Cutter 19mm shank. These high-quality annular cutters deliver the power and durability you need for superior results in mild, aluminium, and structural steels.

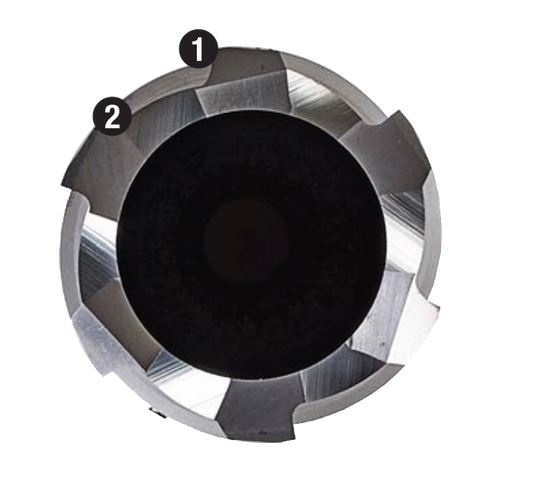

- Increased cutting power and reduced resistance from 2-step geometry

- Optimised tool life – drill more holes per cutter

- Reduced tool wear for clean, burr-free holes

- 25mm depth of cut

- 19mm shank

Engineered for metalworking pros who drill holes all day, JEI’s TurboTM Steel cuts faster and outlasts other cutters. The innovative design improves chip ejection, reduces heat buildup, and powers through workpieces with less resistance. If you’re tired of constantly changing worn-out cutters, upgrade to the Mag Base cutters that help maximize productivity. Drill more holes per cutter and experience cooler, faster cutting in your shop.

Sizes 10 -32mm listed other sizes up to 65mm available to order – contact your local branch.

Some sizes in stock at the supplier and will be 2-3 days delivery.

Available Options:

Description

JEI Turbo Steel HSS Mag Drill Cutter ~ 25mm cut depth (JEICS)

Fast, Accurate and Longer-Lasting

Turbo™ Steel is a high quality fully CNC ground annular / broaching cutter. Turbo™ Steel has a geometry designed to give you fast accurate holes with the benefit of great tool life. A low vibration cutting edge gives stable free cutting action that reduces tool ware. Each tool is hardened to 62-63 ROC so it is able to drill up to 700N/mm2.

Take a look at our video showcasing our HSS cutters in varying cutting depths and lengths.

| JEI Turbo Steel HSS Mag Drill Cutter 19mm shank

Dual Tooth Cutting Geometry The alternating teeth have a two-step design, with each tooth optimised for a different stage of the hole cutting process. This |

|

You may also like…

-

JEI Minibeast Portable Mag base drill 110V – 35mm cutter capacity

£467.93 This product has multiple variants. The options may be chosen on the product page